Updated May 26, 2021

Floor Cleaning Application Spotlight: Metalworking

When you’ve been in the floor cleaning equipment industry for over two decades, like our team at Factory Cleaning Equipment, Inc., you see many clients in a variety of industries looking to resolve dust control issues in the workplace. Using a push broom or a floor scrubber without a dust control system in a dusty environment can results in a significant amount of hazardous airborne debris. Airborne dust and particles can make their way into the lungs of those working on the job site and create a major health hazard. The airborne dust also settles back down onto the ground or onto inventory and can cause damage.

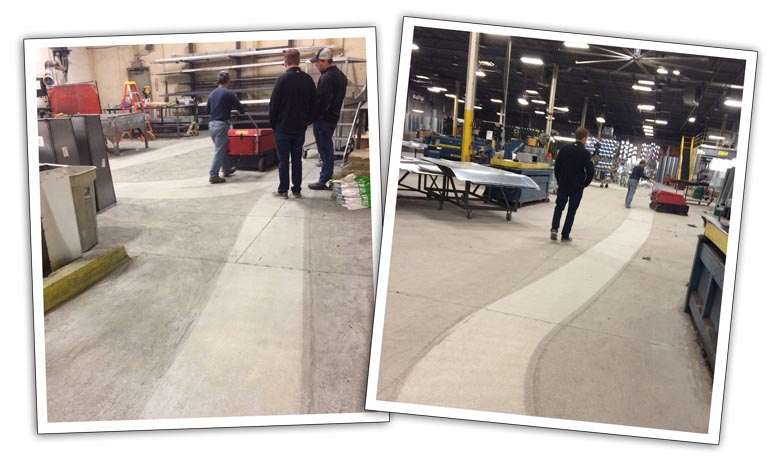

In this case study we highlight the use of an industrial floor sweeper in a Metalworking business dealing with duct fabrication, HVAC unit protection cages, custom fire pits - that’s a significant amount of dust!

Company Problem

This metalworking business was using an ineffective floor scrubber in their shop and was unhappy with the level of cleanliness. The client called Factory Cleaning Equipment and we sent out a representative to assess the facility. This client was using a floor scrubber that wet the floor and, without sweeping the floors first, the dust created in the metalworking facility basically turned to mud. A floor scrubber was not the best equipment for this dusty job site.

Our Solution

Our experienced floor cleaning sales professional quickly realized that this particular metalworking application required an industrial floor sweeper in order to remove the dust and debris. An industrial sweeper does not use any moisture to clean the floors and leaves no residue behind. FCE recommended the Factory Cat 34 walk-behind floor sweeper in addition to the floor scrubber that they already owned. We recommended that the floor be swept daily with a floor sweeper and the floor scrubber should be used intermittently to deep clean the floors as needed. In addition to creating a cleaner environment, using a floor sweeper will also extend the life of their floor scrubber by reducing its frequency of use and limiting the risk of clogging the machine with dust and dirt. Now, this Metalworking business can clean with confidence knowing that they are using the right tools for the job.

Highlights of the Factory Cat 34 Floor Sweeper

The Factory Cat 34 industrial floor sweeper is a high quality piece of American-made equipment with a unique dust control system including a “bag house” type filter that can last the life of the machine in many cases. The Factory Cat 34 can sweep at a rate 10 times faster than what could be swept manually, cleaning up to 30,000 square feet per hour.

If you need help determining whether a floor scrubber or sweeper is best suited for your industrial application, FCE is the best resource for top-quality, American-made industrial floor cleaning machines and concrete finishing equipment. We also offer budget-friendly daily, weekly, and monthly floor sweeper rental rates, which is an excellent option for facilties that don't want to worry about storing and maintaining a floor sweeper long-term. With four locations in Lakeland, FL, Aurora, IL, Mooresville, NC, and Norcross, GA, the Factory Cleaning Equipment technicians can help you select the best floor sweeper to manage dust and maintain OSHA-complaint facilities. Contact Factory Cleaning Equipment online or call us at 800-793-3790.