The latest automatic floor scrubbers are sophisticated machines that are extremely efficient at removing dirt and grime from some of the harshest environments. Whether buying parts, getting the machine serviced, or simply operating the equipment, understanding the components of your floor scrubber is beneficial. Though each machine is unique, here are some general floor scrubber terms that every scrubber owner or operator should be familiar with:

Component Descriptions:

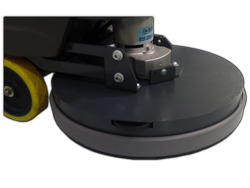

Scrub Head

The scrub head consists of the main brush that is situated at the front of a floor scrubber. A floor scrubber can be configured into a cylindrical machine or disk machine. In a cylindrical configuration, the scrub head on the machine contains two long cylindrical brushes. This type of brush works well for applications with epoxy floors or floors where small debris is expected. The cylindrical machine can eliminate the need to pre-sweep, thus providing a time saving benefit. The powerful disk configured machines are best for applications where the machine will be used on waxed surfaces, pre-swept surfaces, uneven floor surfaces, or multiple floor surfaces. There is a wide variety of disk brush and pad options available, making a disk machine extremely versatile.

Hopper

A hopper is a small, perforated troth located behind the cylindrical brushes on the scrub head that collects debris while the machine is operating. As dirty water and debris are swept into the hopper, the perforation of the hopper allows the water to fall back to the floor to be picked up by the squeegee and deposited into the recovery tank. Once scrubbing is complete, the hopper will contain all of the small debris that was pushed into it by the scrubber brushes.

Squeegee Assembly

As the machine moves forward, the squeegee removes the dirty water and moisture that remains after the brushes on the scrub head clean the floor. One of the benefits of using a floor scrubber is its ability to leave the floors dry after cleaning. The wet floor left behind by a typical mop and bucket can be a slip, trip, or fall hazard for employees and customers. A quality squeegee assembly removes the maximum amount of water and is a very important part of an effective floor scrubber. The blade of a good squeegee assembly is made from durable rubber or silicone compounds and the metal will not corrode over time from contact with floor cleaning chemicals. The unique stainless steel parabolic squeegee with urethane blade that comes standard on the Bulldog Floor Scrubber, for example, will not rust or corrode, even with daily use.

Vacuum System

The vacuum system is the part of the scrubber that allows the squeegee to suck up the excess water and moisture from the floors. After the cleaning solution is sprayed through the scrub head onto the floor and the brushes do their work, the moisture is then removed from the floors through the squeegee by the vacuum fan. The vacuum filter or screen is an important component of an optimally functioning vacuum system. Therefore, it is critical to ensure the filter is always free of debris. If your machine does not have cylindrical brushes or the added pre-sweep option, pre-sweeping is important in order to prevent the vacuum system from clogging with debris. Another tip to keep your vacuum system working at peak performance is to run the vacuum motor for several minutes after the machine is done cleaning. This will help remove excess moisture from the system and therefore lessen the risk of corrosion that could damage to vacuum motor.

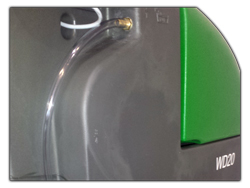

Solution System

The solution system is an automated system that dispenses the water and/or cleaning chemical solution. The clean solution is fed from the solution tank down to the scrub head where it is dispensed onto the floor for cleaning. The hygienic clean solution tank on a floor scrubber ensures that the floors are continually being cleaned with clean water throughout the cleaning process. The operator is able to adjust the amount of solution that is dispensed onto the floors through the operational interface. After each use, the solution tank should be rinsed and left open to help maintain the system.

Recovery System

The recovery system includes the recovery tank where the dirty water that has been collected is stored. By storing the dirty water and clean water separately, dirty water is not able to contaminate the clean water. To collect moisture and soil, automatic scrubbers have a squeegee and vacuum system which collect and carry moisture to the recovery tank. Emptying and rinsing the recovery system after use is an important step for maintaining a floor scrubber. Another maintenance tip to keep the recovery system healthy is to leave the tank open when the machine is not in use to help prevent bacteria growth and odors by ventilating the system.

Power System

Floor scrubbers can be battery-powered, cord-operated, internal combustion powered, gas, LP or diesel powered. Battery operated machines are usually most convenient and you can find tips for maintaining your floor scrubber battery in the article, Taking Care of Your Floor Scrubber & Sweeper Batteries is Easy.

Operational Interface

The operational interface is the part of the machine that the operator interacts with when the machine is in use. Many of today’s machines have sophisticated yet user friendly controls. Ergonomic features, like Tennat’s TouchN-Go™ control panel featuring 1-STEP™ scrubbing, are important on a floor scrubber and the operational interface is where you see many of those features.

Floor scrubbers have the ability to increase productivity and workplace safety while maintaining a variety of floor surfaces. At Factory Cleaning Equipment, our experts with over 20 years in the floor cleaning equipment industry can help guide you to the ideal machine for your needs. Although some components are universal to virtually all floor scrubbers, there are many unique floor scrubber models on the market so it is important to consult a professional to ensure the machine’s quality parts and features will serve your business for many years to come. For a free demonstration of any of our floor scrubbers, contact us today: 800-793-3790.